DIN 1.2083 Plastic Mould Steel

Description

1.2083 mold steel, also known as X42Cr13, is a high-quality stainless tool steel primarily used in plastic mold manufacturing. It features excellent corrosion resistance, making it ideal for molds exposed to moist environments or corrosive plastics. With good polishability and wear resistance, 1.2083 is suitable for applications requiring a high surface finish, such as optical or medical molds. It also offers good dimensional stability during heat treatment. Due to its high chromium content, it maintains hardness and durability while resisting rust. This steel is widely used in the production of injection molds, especially for PVC and other aggressive plastics.

DIN 1.2083 Plastic Mould Steel:

Equivalent grades: DIN 1.2083/ X42Cr13, 420, S136

Chemical composition:

|

C |

Si |

Mn |

Cr |

V |

P |

S |

|

0.38-0.45 |

0.30-0.50 |

0.20-0.40 |

12.00-13.50 |

0.18-0.30 |

0.03max |

|

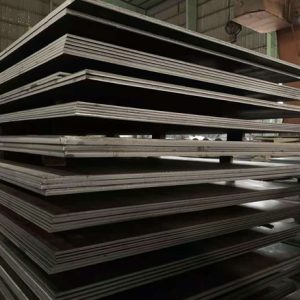

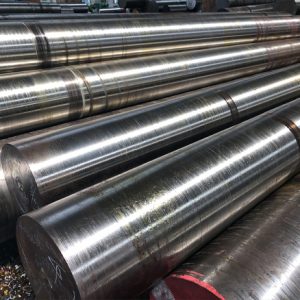

Available sizes: Round dia 16mm to 600mm; flat 16 – 400mm x 200 – 800mm

Manufacture: EF/ESR, hot forged/ hot rolled

Surface condition: black/grinded/rough turned/milled

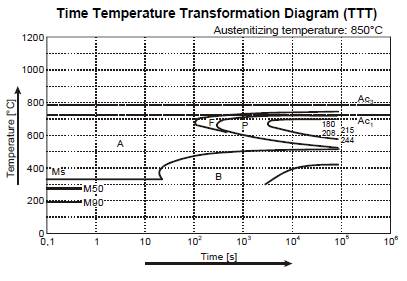

Delivery condition: annealed/quenched and tempered

Hardness: annealed, 229HBS max/ after Q+T, hardness 31-35HRC

Characteristics: good anti-rusty capacity, polishing capacity, super intensity and wearable capacity.

Applications: corrosion resistance and wear resistance of high quality plastic mould, transparent plastic mould.

(All technical information is for reference only)