DIN 1.2367/X38CrMoV5-3 Hot Work Mold Steel

Description

1.2367 steel, also known as X38CrMoV5-3, is a high-performance hot work tool steel recognized for its exceptional toughness, thermal stability, and resistance to wear and heat checking. It is specifically designed for use in demanding hot work applications such as die casting, hot forging, and extrusion tools. The steel maintains its strength and hardness at elevated temperatures, ensuring long tool life under thermal and mechanical stress. 1.2367 also offers excellent tempering resistance and can achieve a fine balance of hardness and ductility through heat treatment. Its high toughness reduces the risk of cracking, making it ideal for complex, high-pressure tooling environments.

Hot work tool steel 1.2367

DIN 1.2367/X38CrMoV5-3

Chemical composition:

|

C |

Si |

Mn |

Cr |

Mo |

V |

P, S |

|

0.35-0.40 |

0.10-0.40 |

0.20-0.40 |

4.70-5.20 |

2.70-3.30 |

0.40-0.70 |

0.03 max |

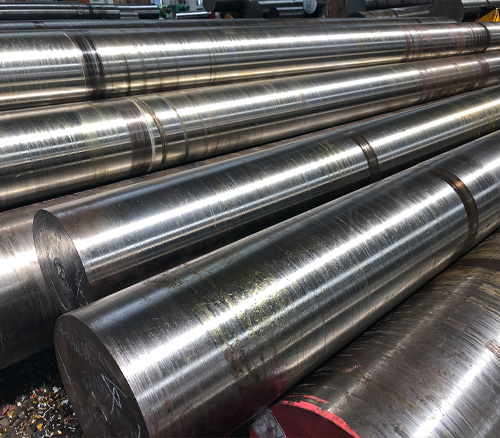

Available sizes: Round dia 16mm to 600mm; flat 16 – 400mm x 200 – 800mm

Manufacture: EFS/ESR, hot forged/ hot rolled

Surface condition: Black/grinded/rough turned/milled(machined)

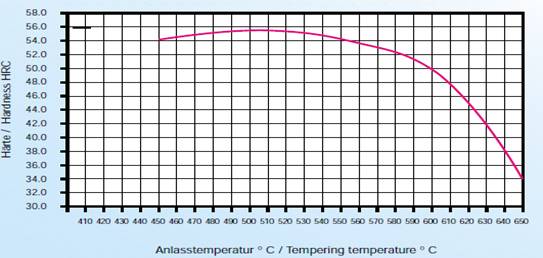

Delivery condition: annealed/ quenched and tempered

Hardness:annealed, 220HBS max/ hardness after quenched and tempered as per buyer’s requirement

Characteristics: good macro and microstructure with lowest levels of segregation, very good polishability, good thermal conductivity, high dimensional stability during heat treatment, good machinability, high working hardness for increased service life.

Applications: heavy duty hot work tool and dies, mainly for light alloy processing: mandrels, dies, and containers for metal tube and rod extrusion equipment; tools and dies for the manufacture of hollow bodies, screws, rivets. Die casting equipments, forming dies, die inserts, hot shear blades, and plastic moulding dies.

(All technical information is for reference only.)