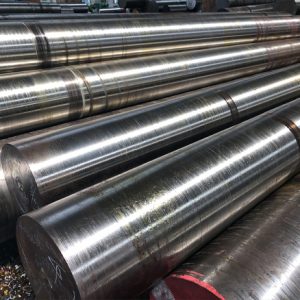

C35 Carbon Steel | DIN 1.0501 | AISI 1035 | S35C

Description

SAE 1035 steel is a medium-carbon, non-alloy steel that offers a good balance of strength, toughness, and machinability. With approximately 0.35% carbon content, it has higher strength and hardness than low-carbon steels, while still maintaining decent ductility and weldability. SAE 1035 can be heat treated, such as through quenching and tempering, to improve its mechanical properties for more demanding applications. It is commonly used in the manufacture of automotive components, axles, shafts, gears, bolts, and other machinery parts. Its versatility and moderate cost make it a popular choice for general engineering and structural applications that require improved mechanical performance over lower carbon grades.

1.C35 steel Supply Form & Size

| Form of Supply | Size(mm) | Length(mm) |

| Round bar | Φ6-Φ1000 | 3000-10000 |

| Square bar | 100 x 100-600×600 | 3000-6000 |

| Flat bar/Blcoks | Thickness :120-800 | 2000-6000 |

| Width:120-1500 |

2.Surface Finish&Tolerance

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

3. C35 Steel Chemical Composition&Related Specifications

| Grade | C | Si | Mn | P | S |

| C35/1.0501 | 0.32-0.39 | ≤ 0.4 | 0.50-0.80 | ≤ 0.045 | ≤ 0.045 |

| USA | UK | China | Japan |

| 1035 | 080M36 | 35# | S35C |

4. C35 Steel Mechanical Property

| Diameter d mm | ≤ 16 | 16-40 | 40-100 |

| Thickness t mm | < 8 | 8-20 | 20-60 |

| Yield Strength Mpa | ≥430 | ≥380 | ≥320 |

| Tensile Strength Mpa | 630-780 | 600-750 | 550-700 |

| Elongation, % | ≥17 | ≥19 | ≥20 |

| Reduction of area ,% | ≥40 | ≥45 | ≥50 |

5.C35 steel Forging

Forging temperature:950-1200℃,air cooling after forging.

6. C35 Steel Heat Treatment

- Annealing

Full annealing is carried out from 840-890ºC, followed by furnace cooling at 28ºC per hour, to 650ºC soaking and air cooling.

- Normalizing

The normalizing temperature range for this grade is typically 860-900ºC,followed by cooling in still air.

- Hardening

Hardening of C35 steel is carried out from an austenitizing temperature of 830-860ºC,followed by oil or water quenching.

- Tempering

Tempering after normal hardening and oil or water quenching is carried out at 550-680ºC to give the required mechanical properties as determined by practical experience.

7.C35 Steel Application

C35 steel is one of the most widely used for machinery parts,and used for forged parts where the strength and toughness of the material are appropriate.The following are the major applications of C35 carbon steel:

- Levers

- Bolts

- Nuts

- Studs

- Gears

- Forged shafts

- Axles