O1/1.2510 Cold Work Tool Steel

Description

O1 steel, also known as 1.2510 or 100MnCrW4, is a high-carbon, oil-hardening cold work tool steel known for its excellent dimensional stability, high hardness, and good wear resistance after heat treatment. It offers good machinability in the annealed state and can achieve a fine, even structure through proper heat treatment, making it suitable for precision tools requiring sharp edges and minimal distortion. O1/1.2510 is commonly used for knives, punches, gauges, cutting tools, and molds where high surface hardness and durability are critical. It provides a good balance between toughness and abrasion resistance, making it a reliable choice for both industrial applications and fine toolmaking.

Cold work tool steel/ oil steel O1

Equivalent grades: O1, 9CrWMn, 1.2510/100MnCrW4, SKS3

Chemical Composition:

|

C |

Si |

Mn |

Cr |

W |

V |

P |

S |

|

0.90-1.05 |

0.15-0.35 |

1.00-1.20 |

0.50-0.70 |

0.50-0.70 |

0.05-0.15 |

0.03MAX |

0.03MAX |

Available sizes: Round dia 16mm to 600mm; flat 16 – 400mm x 200 – 800mm

Smelting & Shaping: EF/ ESR+ hot forged/ hot rolled

Surface Condition: Black surface/ Grinded/ Machined

Delivery Condition: Annealed

Annealed Hardness: HB210MAX

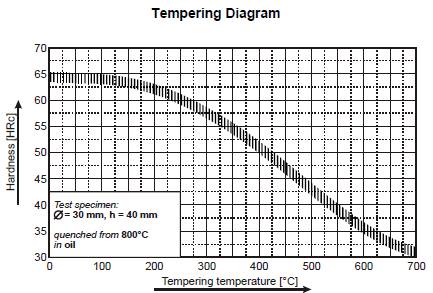

Hardness & Tempering Curve:

Characteristics:

High wear resistance

High surface hardness after tempering;

Good dimensional stability during heat treatment;

Good machinability

Applications:

Cutting and punching tools, shear knives, thread rolling tools, measuring instruments, platinum using molds.

(All technical information just for reference only)