AISI 8620 Alloy Steel | DIN 1.6523 | 20NiCrMo2-2

Description

AISI 8620 steel is a low-alloy, case-hardening steel known for its excellent toughness, core strength, and wear resistance after carburizing. It contains nickel, chromium, and molybdenum, which improve its hardenability and mechanical properties. After carburizing and quenching, AISI 8620 achieves a hard, wear-resistant surface with a tough, ductile core, making it ideal for components subjected to high surface stress and impact.

This steel is widely used in the automotive and machinery industries for gears, shafts, camshafts, crankshafts, and other parts requiring a hard outer layer with a tough interior. It also offers good machinability and weldability in its annealed state. AISI 8620 is favored for applications requiring a combination of surface hardness and core strength.

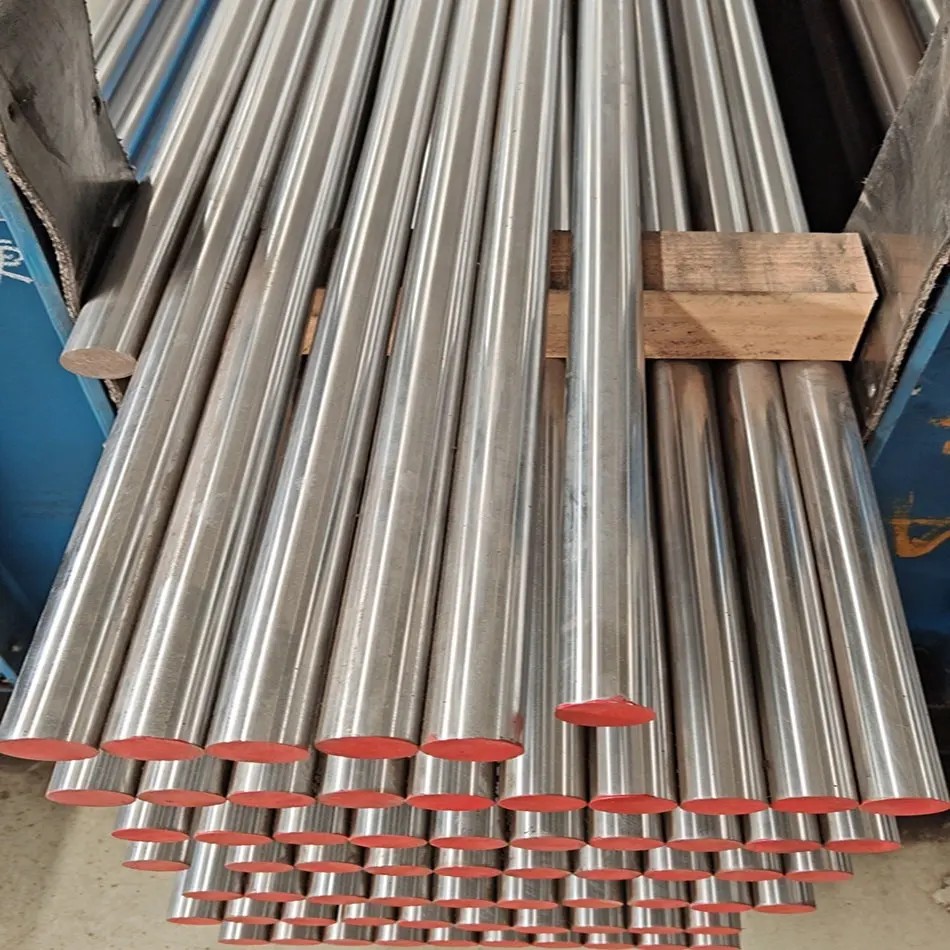

1.AISI 8620 steel Supply Form & Size

| Form of Supply | Size(mm) | Length(mm) |

| Round bar | Φ6-Φ1,000 | 3,000-10,000 |

| Square bar | 100×100-600×600 | 3,000-6,000 |

| Plate/Sheet | Thickness :20-400 Width:80-1,000 |

2,000-6,000 |

| Flat bar/Blcoks | Thickness :120-800 Width:120-1,500 |

2,000-6,000 |

2.Surface Finish&Tolerance

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

3.Chemical Composition&Related Specifications

| C | Mn | P | S | Si | Ni | Cr | Mo |

| 0.18-0.23 | 0.7-0.9 | ≤ 0.035 | ≤ 0.04 | 0.15-0.35 | 0.4-0.7 | 0.4-0.6 | 0.15-0.25 |

| Germany | UK | China | Japan |

| 1.6523/20CrNiMo2-2 | 805M20 | 20CrNiMoA | SNCM220 |

4.Mechanical Property

Section Size 25 mm, Water Quenched at 830°C

| Tempering Temperature °C | Tensile Strength Mpa | Yield Strength Mpa | Elongation % | Impact Izod J | Hardness HB |

| 205 | 1050 | 765 | 18 | 80 | 311 |

| 425 | 930 | 800 | 20 | 110 | 275 |

| 650 | 700 | 556 | 30 | 140 | 207 |

AISI 8620 Mechanical Property -Normalizing(+N) Vs Annealing(+A)

| Tensile,Mpa | Yield,Mpa | Elongation,% | Reduction,% | Charpy Impact, J | Brinell Hardness,HB | |

| +N | ≥635 | ≥355 | ≥26.3 | ≥60 | ≥100 | 183 |

| +A | ≥535 | ≥385 | ≥31.3 | ≥62 | ≥112 | 149 |

5.Forging for AISI 8620

- Heat the temperature to 1150-1200°C uniformly and slowly;

- Keep the temperature stable for steel to be heated throughout the section;

- Reheat the steel when forging temperature below 850°C;

- Cool slowly in ashes or sand after forged

6.Heat Treatment

- Normalizing:900°C – 925°C ,Cooling in air

- Annealing: 820°C – 850°C,Cooling in furnace

- Caburizing: 900°C – 925°C

- Core Refine:Reheat temperature to 840°C – 870°C during slow cooling after carburized,hold enough time for the steel to be heated uniformly, quench as required in water, oil or air cool.

- Case Hardening:Reheat the steel to 780°C – 820°C after core refining, hold enough time for the steel to be heated uniformly, and quench in oil.Followed by tempering as soon as possible.

- Tempering:150°C – 200°C,cool in still air

- Nitriding:490°C – 530°C,slow cooling

7.Application

AISI 8620 is used extensively by all industry sectors for light to medium stressed components and shafts requiring high surface wear resistance with reasonable core strength and impact properties,and can be used for high tensile applications uncarburised but through hardened and tempered.Typical uses are: Arbors, Bearings, Bushings, Cam Shafts, Differential Pinions, Guide Pins, King Pins, Pistons Pins, Splined Shafts, Ratchets, Sleeves etc