DIN 1.2316 / X38CrMo16 Plastic Mould steel

Description

1.2316 steel, also known as X38CrMo16, is a high-quality stainless tool steel designed for plastic molds requiring excellent corrosion resistance and high surface finish. With a high chromium content and added molybdenum, 1.2316 offers superior resistance to wear, humidity, and corrosive plastic materials like PVC. It provides good polishability, toughness, and dimensional stability after heat treatment. This makes it ideal for molds used in medical, optical, and food packaging industries, where hygiene and high surface quality are critical. 1.2316 is often chosen for producing transparent or chemically aggressive plastic products, ensuring long mold life and consistent performance under demanding conditions.

DIN 1.2316/ X38CrMo16 High Alloy Plastic Mould Steel, Stainless Steel

Equivalent grade-GB 3Cr17NiMo

Chemical composition: (%)

|

C |

Si |

Mn |

Cr |

Mo |

Ni |

P |

S |

|

0.33-0.45 |

1.00max |

1.00max |

16.00-17.00 |

1.00-1.30 |

0.60-1.00 |

0.03max |

|

Available sizes: Round dia 16mm to 600mm; flat 16 – 400mm x 200 – 800mm

Manufacture: EF/ESR, hot forged/ hot rolled

Surface condition: black/grinded/rough turned/milled

Delivery condition: annealed/quenched and tempered

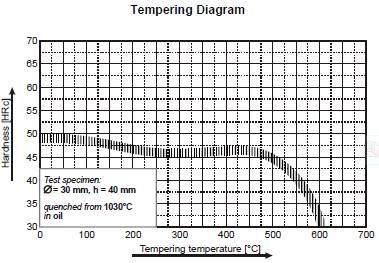

Hardness: annealed, 230HBS max/ after Q+T, hardness as per buyer’s requirement

Characteristics: stainless martensitic steel with increased Cr content, improved the corrosion resistance. Very good polishability.

Applications: tools and moulds for corrosive plastics and polymers, food industry.

(All technical information is for reference only)