DIN 1.2312/AISI P20+S Plastic Mould steel

Description

1.2312 steel, also known as P20+S, is a pre-hardened plastic mold steel enhanced with sulfur for improved machinability. It is typically delivered at a hardness of 280–325 HB and offers excellent machinability, making it ideal for high-speed and precision machining processes. 1.2312 maintains good toughness, dimensional stability, and surface finish quality, making it suitable for medium to large injection molds and mold bases. Though not corrosion-resistant, it performs well in dry environments and can be nitrided for enhanced surface hardness. Widely used in the automotive and consumer product industries, it is favored for molds with short to medium production runs.

1.2312/AISI P20+S Plastic Mould Steel

Equivalent grades: DIN 1.2312/ 40CrMnMoS8-6, AISI P20+S

Chemical composition: (%)

|

C |

Si |

Mn |

Cr |

Mo |

P |

S |

|

0.35-0.45 |

0.30-0.50 |

1.40-1.60 |

1.80-2.00 |

0.15-0.25 |

0.03max |

0.05-1.10 |

Available sizes: Round dia 16mm to 600mm; flat 16 – 400mm x 200 – 800mm

Manufacture: EF/ESR, hot forged/ hot rolled

Surface condition: black/grinded/rough turned/milled

Delivery condition: annealed/quenched and tempered

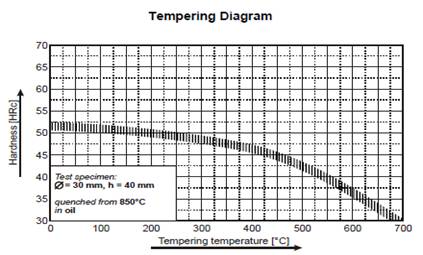

Hardness: annealed, 235HBS max/ after Q+T, hardness 28-35HRC

Characteristics: with additional sulphur, usually supplied in a quenched and tempered condition. Polishable, better machinability compared to 1.2311.

Applications: plastic moulds, frames for plastic pressure dies, hydroforming tools

(All technical information is for reference only)